I have seen several articles regarding the Biqu Hurakan being referred to as, “Yet another Chinese bed slinger.” However, from what I am seeing, it seems to be much, much more.

While it can be classified as a “bed slinger”, it is the first to come with Klipper firmware out of the box. This means it is capable of input shaping and pressure advance to help improve overall print quality and reduce surface artifacts. At $369, it includes a host of features and hardware that are typically on the “upgrades” list for most other printers in this category.

You may be asking yourself, “How does Biqu offer a printer with Klipper when I cannot even buy a Raspberry Pi?” The answer to this question would be that Biqu and BigTreeTech have been working on their own hardware. In the case of the Hurakan, this would be the BTT Manta M4P+CB1. The brains of the machine would be the Manta M4P main control board and the CB1 core board.

By developing their own hardware, Biqu was able to bring to market a printer yet to be seen at a reasonable price.

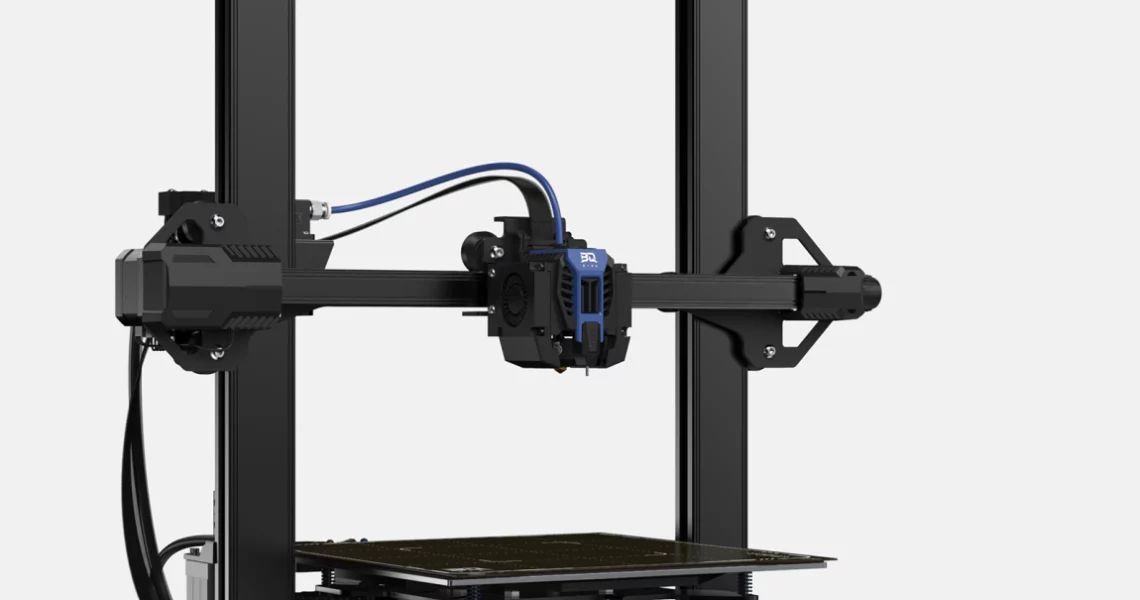

The Biqu Hurakan, an upcoming Cartesian 3D printer that runs Klipper firmware out of the box (Source: Biqu)

OVERVIEW

The Biqu Hurakan has a build volume of 220 x 220 x 270 mm. At that size, it is not the largest, or the smallest, but will suffice for most 3D Prints out there. You will see 260 °C and a maximum bed temperature of 100 °C, with a Bowden extruder. These specs mean you will be fine to print with standard filaments like PLA, ABS, PETG, and TPU. And yes, I was able to print TPU on this machine with the Bowden extruder without issue.

Biqu is not only developing amazing printers and hardware but there are also a host of Biqu parts for upgrading the Hurakan even further in the works. Those include the Biqu H2 extruder, HDMI5/HDMI7 screen, Dual Z-Axis upgrade kit, and a Biqu Camera.

BENEFITS OF KLIPPER?

Cartesian 3D Printers, or Bed Slingers, with similar build volume and feature sets, are fairly plentiful. The major difference is that the Hurakan is running Klipper firmware versus the fairly standard Marlin firmware. A first of its kind.

We won’t go deep into what Klipper firmware is or how it differs from Marlin, at least not in this article. However, we will highlight some of Klippers major features that help reduce print head vibrations to reduce ringing, echoing, or ghosting. A couple of those features are input shaping and pressure advance.

Input shaping is unique to Klipper, which aims to reduce the ringing/ghosting effects in your 3D prints. Ringing occurs due to the vibrations produced when printing at high speeds. It approximates the vibrations of the printer’s movements and computes the pathways that will cancel out these vibrations. Klipper aims to balance the print quality at high speeds with this feature. (Klipper3D, 2022)

This feature is a replica of the Marlin’s Linear advance. Klipper’s smooth pressure advance gives you the same functionality and helps to reduce filament stringing. But, it’s much easier to calibrate and adjust the value pressure advance value in Klipper than in Marlin. You can set this value in real-time without needing to reflash the firmware or edit any gcode files. (Klipper3D, 2022)

Klipper also uses a much more sophisticated motion processing that allows a higher, finer level of detail. Meaning it can process many more steps per second than Marlin. All resulting in high-quality prints that complete faster.

HURAKAN ELECTRONICS – MANTA AND CB1 BOARDS

The standard 32-bit MCU, or mainboard, does not contain the processing power required to run Klipper. To do so requires an external board or device, like a Raspberry Pi. However, due to the mass shortage of available Pi’s, Biqu decided to develop their own in the aforementioned CB1 single-board compute module to accompany their new Manta series of mainboards. The design of these boards utilizes components that are readily available and cost-effective.

Inside the Hurakan, lies a Manta M4P 32-bit board based around a 64MHz ARM STM32H0B0RE, plus a CB1 4-core Cortex-A53@1.5GHz with 512M DDR3 memory. With this, Biqu can produce a machine that runs Klipper natively and remains competitively priced.

CONNECTIVITY OPTIONS – WIFI AND ETHERNET

The Hurakan includes Wifi and a 100 Mbps Ethernet port, plus dual female USB-A ports to connect a USB camera, USB flash drive, or other USB-compatible devices.

There’s also an external SPI port to connect an ADXL345 accelerometer module to calibrate input shaping. The bed and print head include special mounting points for the module.

WEB GUI

Klipper can be controlled via a Fluidd or Mainsail Web GUI, providing an easy way to interact with the machine remotely from any web browser. The Hurakan does include a built-in LCD display for convenience but it is not necessary to use.

AUTOMATIC BED LEVELING

Anyone who has been 3D printing for a while can understand that manual bed leveling can be a difficult thing to maintain. Thankfully, the Hurakan includes a Biqu MicroProbe to help get the first layers down consistently and provide a smooth printing experience. Biqu’s self-developed probe is similar to a BLTouch or CR Touch, but much lighter at only 6 grams and around a ⅓ the length of a standard probe.

BED HEATING WITH A TWIST

Another neat feature during a time of increased power costs is the option to reduce power consumption with a switch on the bed. When set to 100 W, only the center of the bed will heat, and when set to 240 W, the entire bed heats. Providing an option to save power on small objects that only need the center of the bed heated.

ADDITIONAL FEATURES

Some additional features to consider:

- Filament runout detection

- Tensioners on X and Y belts

- LED Light on Nozzle

MY EXPERIENCE

Since receiving and running Biqu’s Hurrakan for about a week, I have not stopped smiling! The machine is almost perfect and is so much fun to use. It includes just the right amount of features I could print with it for years and never touch it. However, it leaves just the right amount of “upgradability” for it to still be fun for makers and tinkerers like me.

At this price point, I may just acquire a second one to tinker with, while leaving the first one completely stock.

DIMENSIONS AND SPECS

3D Printer Name

BIQU Hurakan

3D Printer Dimensions

480x470x482mm

Print Head

1 PC

Nozzle Diameter

Standard 0.4mm

Firmware

Klipper

Slicing Software Compatibility

Cura/Repetier-Host/Simplify 3D…

Output Voltage

24V

Heated Bed Power

100W/240W

Maximum Temperature of Nozzle

260℃

Suggested Printing Speed

60mm/s

Filament

PLA/ABS/PETG…(Any material with print temp lower than 260℃ including flexible filament with 95A stillness.)

Build Volume

220x220x270mm

Layer Thickness

0.1mm-0.3mm

Printing Accuracy

±0.05mm

File Format

G-code

Printing Method

USB Drive/LAN Controlled

Rated Power

280W

Maximum Temperature of Heated Bed

100℃

Default Speed Limit(Firmware)

180mm/s

Filament Runout Detection

Standard Feature

Rated Voltage

100-120V/200-240V

50/60 Hz

Klipper3D (November, 2022). Resonance Compensation. https://www.klipper3d.org/

Biqu (November, 2022). Biqu Hurakan. https://biqu.equipment/collections/3d-printer/products/biqu-hurakan-diy-3d-printer?variant=40089640960098